- +41 41 982 04 12

- info@kelch.ch

- Mon - Fri: 8:00 - 17:00

Tool measurement

User-friendly operation based on manual and / or CNC controlled measurement. Fast, simple and efficient tool measurement with comprehensive tool setting software. Tool measurement V3 with comprehensive software for tool setting.

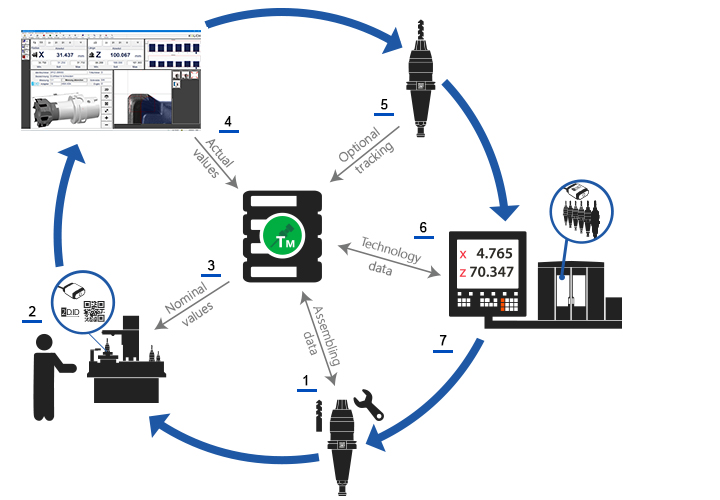

Cycle

In the MyXPert® database, an item is always viewed from two sides, logistically and technically. This extended view supports technicians and simplifies logistical processes.

Tool identification

Our unique 2D code structure makes tedious searching a thing of the past. With the help of the 2D code, we accelerate your production processes and increase your efficiency.

MyXPert

Tool cycle

- Tool assembly according to MyXPert database template

- The 2D.ID code is scanned on the presetting device V3.

- Target data appears automatically on the Kelch presetting device V3.

- Saving the measured values in the database

- Transaction data is stored in the history (tracking)

- Writing the technology data directly into the controller

- After the service life has expired, the process starts again

Simple, fast and precise measurement with the Industrial Line V3 presetter!

V3

Time saving

High time savings in set-up and process times

from the very first application.

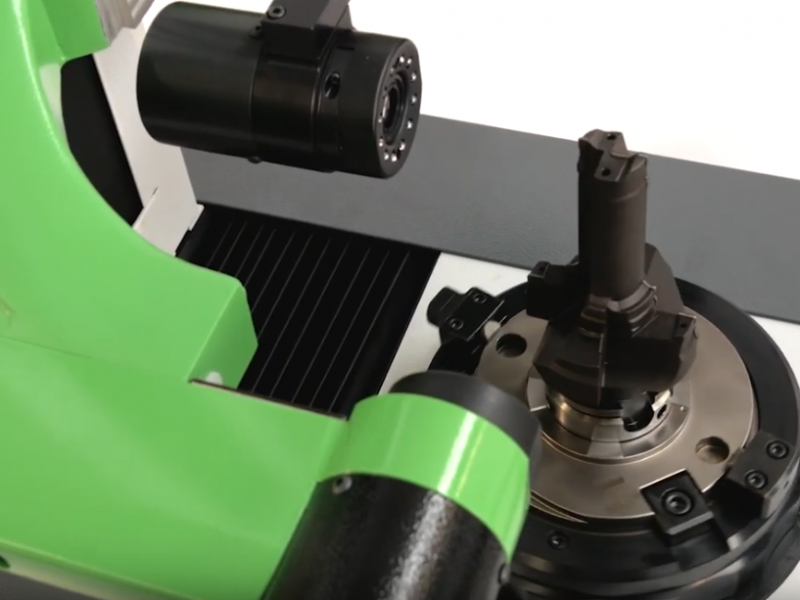

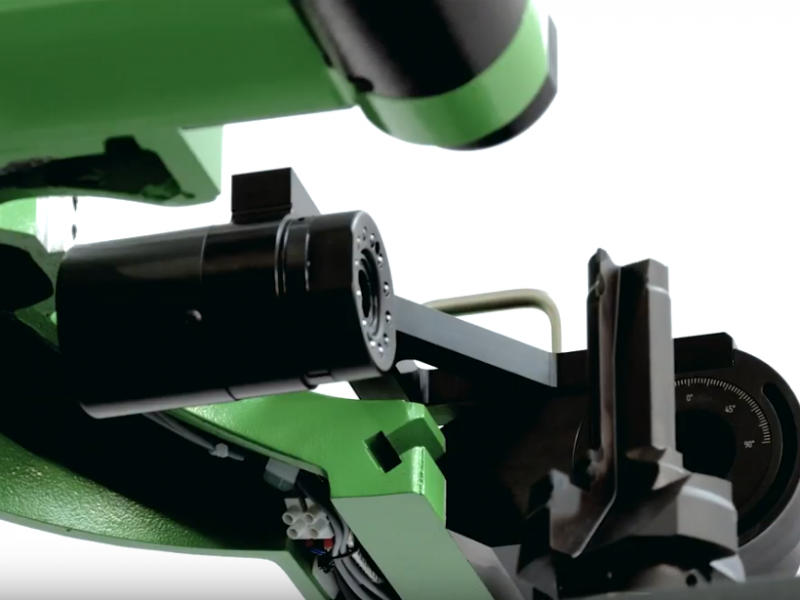

CMOS camera

CMOS camera with precise optics and illumination for repeatability of ± 2 μm.

Axes setting

Fine adjustment in both axes for μm-accuracy of the X and Z directions.

Table equipment

Variable table equipment with

Tool holder and spindle.

2D.ID

With a 2D scanner, the 2D.ID codes can be scanned directly without input errors.

Example structure

with three tool holders and

of a CNC spindle.

No conversion

Thanks to the control system, the binary

codes can be controlled directly.

Ergonomics

The quick-action axis adjustment enables

ergonomic working.

Adapter management

Thanks to the MyXPert database management, all adapter values are stored in the system.

One

Device

Two sizes

Bring out the best in yourself and your business.

V346

-

Vertical measurement

-

Measuring length X (ø) 400mm

-

Measuring length Z 600mm

-

Weight 300kg

-

1.267 x 570 x 1.273mm

-

Software Easy-2D.ID Set

-

Material nodular cast iron

V366

-

Vertical measurement

-

Measuring length X (ø) 600mm

-

Measuring length Z 600mm

-

Weight 300kg

-

1.267 x 570 x 1.273mm

-

Software Easy-2D.ID Set

-

Material nodular cast iron

Optional

available

Ask us!