- +41 41 982 04 12

- info@kelch.ch

- Mon - Fri: 8:00 - 17:00

Discover the world of Kelch service now!

Simplified digital measurement of the pull-in forces!

Digital measurement

The measurement result is shown directly on a display and can be read in plain text. This simplifies a measurement considerably due to digital measurement data. This simplifies a measurement considerably due to digital measurement data.

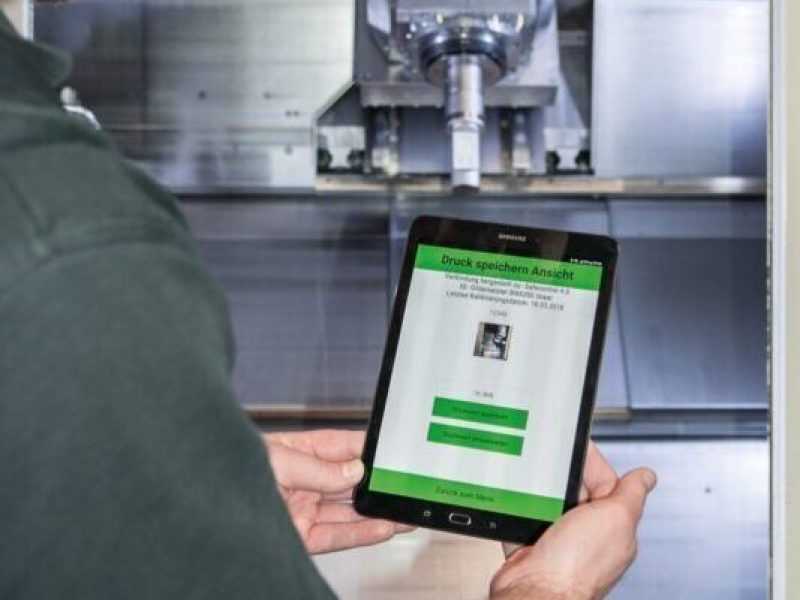

Tablet Solution

The new solution for Bluetooth between the instrument and the tablet ensures more accurate data and improved safety at work.

Quality Management

Calibration and repair service with Safecontrol 4.0 is an important component for quality assurance and process/work safety in state-of-the-art production!

Safecontrol 4.0

Digital measuring system for detecting the retraction forces of machine tool spindles, as well as extensions, reductions and zero-point clamping systems.

Digital measurement of pull-in forces for tablets and smartphones

Safecontrol 4.0

No adapter

One base unit suitable for all adapters (from HSK, PSC and up to SK)

Paperless

With digital measurement, you can now work paperless while protecting the environment.

Bluetooth

Data is displayed on a tablet PC via Bluetooth connection.

Quality Management

Calibration and repair service Safecontrol 4.0 - is an important component for quality assurance as well as process and work safety in production!

Measurement precision

A high measuring precision is given by (0.5 % of the measuring range end value) as well as a large measuring range (0-100 kN)

Reliability

After clamping in the machine spindle, a fast, trouble-free and reliable measurement is obtained immediately.

Measured value display

For better readability and identification of the spindles, the measured value display was integrated into the handle using a display with position orientation.

Handling

The solid holder and ergonomic handle make the Safecontrol easy, fast and efficient to operate.

Tablet Solution

The new Bluetooth solution between the measuring device and the tablet ensures more accurate data and safety at work.