- +41 41 982 04 12

- info@kelch.ch

- Mon - Fri: 8:00 - 17:00

Tool measurement

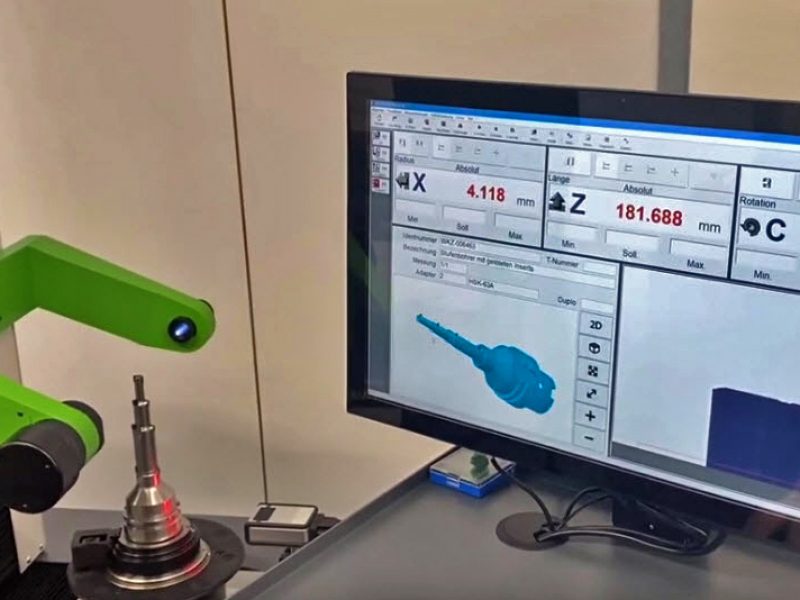

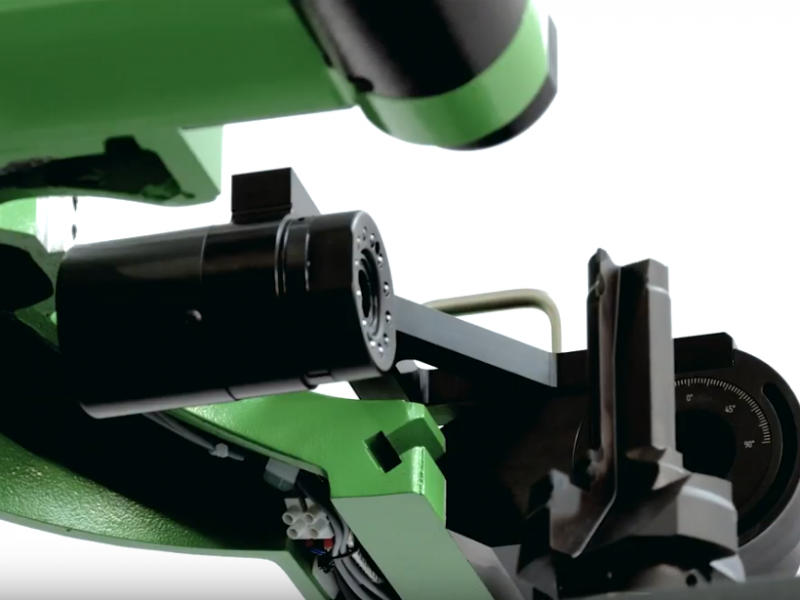

User-friendly operation based on manual and / or CNC controlled measurement. Fast, simple and efficient tool measurement with comprehensive tool setting software. Tool measurement V3 with comprehensive software for tool setting.

ToolManager

In the MyXPert® database, an item is always viewed from two sides, logistically and technically. This extended view supports technicians and simplifies logistical processes.

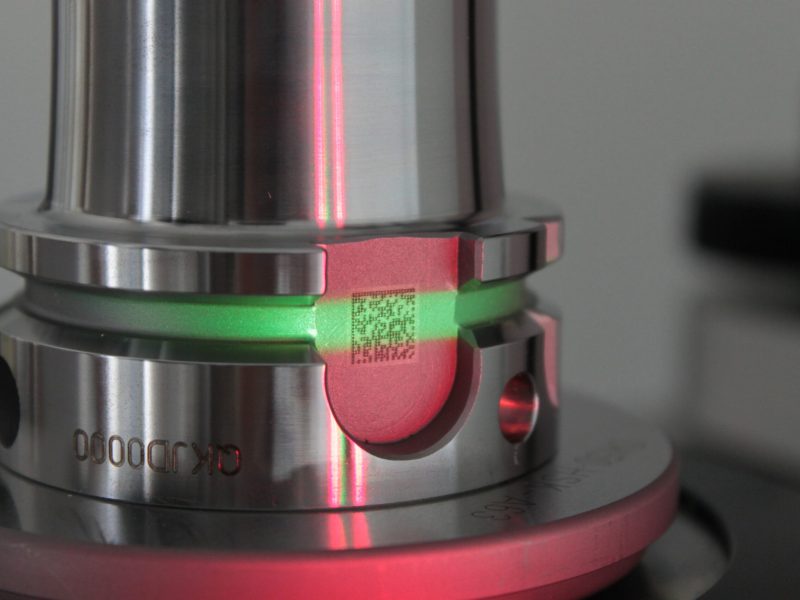

Tool identification

Our unique 2D code structure makes tedious searching a thing of the past. With the help of the 2D code, we accelerate your production processes and increase your efficiency.

Another module of the

MySolutions Smart-Factory All-in-One Solution!

MyXPert

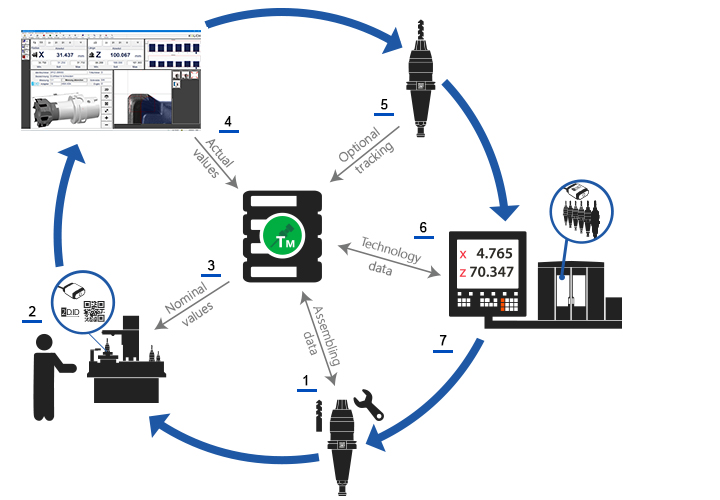

Tool cycle

- Tool assembly according to MyXPert database template

- The 2D.ID code is scanned on the presetting device V3.

- Target data appears automatically on the Kelch presetting device V3.

- Saving the measured values in the database

- Transaction data is stored in the history (tracking)

- Writing the technology data directly into the controller

- After the service life has expired, the process starts again

With the Kenova -Pi SFS package, all elements of a BOM for a machining tool that is being measured can be visualized with just one click.

Kenova

ToolManager

With the dual structure of the MyXPert ToolManager, all modules are managed centrally. All data accesses, from the logistical or technical area, are consistently available in all process levels.

Tool identification

Scan directly at the tool, manage data centrally and monitor in real time

Process integration

The PI stands for simple Process Integration in its most flexible and unlimited form.

Make your tool-presetter smart

Kenova PI -

With the dual structure of the MyXPert ToolManager, all modules are managed in a centralized way. All data accesses, whether from the logistical or technical area, are consistently available in all process steps.

With the KENOVA-π SFS package, all elements of the BOM for the machining tool to be measured can be visualized with a single click. The Pi symbol is an abbreviation for simple process integration in its most flexible and unlimited form. All information such as the storage location and its stock information including minimum, maximum, rotating stock etc., 2D/3D CAD graphics as well as an automatic order execution are available on demand. This massively increases tool availability and thus also reduces unnecessary machine downtime.

In combination with intelligent storage systems (e. g. Lean-Lift, Paternoster, etc.), you have your total stocks centrally managed and in view in real time at all times. Logical system defaults prevent incorrect bookings by unauthorized personnel and thus generate a controlled booking of the complete tools or their individual components.

Illegal stocks entries are therefore practically eliminated and allow optimum cost control of all operating resources. Due to the consistent implementation with standard modules, a process integration to existing third-party systems (ERP, MES, etc.) is also easily possible.

At the simple mouse click, you know where a tool component (e. g. inserts, lathing bars, etc.) is currently located or for which order it is required in a complete tool. This enables significant optimization and considerable time/cost savings in production.

With the KENOVA-π SFS package, it’s no longer a matter of searching, instead it’s a matter of finding.

one solution for all sizes

Make your tool-presetter smart

V3, V6 & V9

-

Tool measurement

-

Measuring length X Ø and Z

-

Fast, simple & accurate

-

High quality component

-

Machining companies

-

Manual and CNC controlled

Integration

-

System and device interface

-

2D.ID Scanner

-

Tool identification

-

Logistics

-

All data centralized

-

Further software solutions